The 7 Most Dangerous Infrared Thermography Mistakes (and How Professional Training Prevents Them)

- Christopher Casey

- 3 days ago

- 6 min read

Infrared cameras have never been easier to buy or use.

They’re compact, affordable, and produce crisp images that might make thermography seem like a simple “point-and-check” exercise. That false sense of simplicity is exactly what gets people into trouble.

Every week at Monroe Infrared (a Guidant Power company), we meet technicians who bought a camera, tried to self-teach, and quickly discovered that thermal imaging is far more complicated than it appears on the screen. They usually tell us some version of, “I thought I understood this. I didn’t realize how much I was missing.”

The reality is straightforward: thermography is powerful, but only when performed correctly. Misinterpret one image and you can create unnecessary panic, or overlook a real hazard hiding in plain sight. With NFPA 70B now requiring condition-based maintenance and qualified personnel for infrared inspections, the margin for error has shrunk dramatically.

Below are the seven most dangerous mistakes untrained thermographers make, why they happen, and how proper training eliminates them.

Mistake #1: Believing That “Hot Equals Bad” and “Cool Equals Good”

This is the most common (and the most misleading) assumption beginners make. Thermal images feel intuitive: bright colors look alarming, and cooler tones feel safe. But infrared images aren’t emotional; they’re contextual.

A component can look hot simply because:

It’s designed to operate at a higher temperature

It has low emissivity, or

It’s made of a material that naturally radiates heat differently.

Likewise, a cool-looking component isn’t always healthy. Low load, airflow patterns, shading, or compensating mechanical processes can mask genuine issues.

Training teaches thermographers how to evaluate heat in context, not in isolation. That includes comparing similar components under similar load, identifying expected temperature profiles, and understanding material behavior. Without context, you’re just guessing.

Mistake #2: Measuring Equipment Under the Wrong Load

Infrared thermography depends heavily on load. A component inspected at 10% load tells you almost nothing about how it behaves during normal or high-load operation. A breaker that seems perfectly normal during light use might spike dangerously when the system is fully energized.

Many untrained thermographers unknowingly perform inspections when equipment is starting up, shutting down, or idling. They report that everything “looks fine,” because at that moment it is. But this creates a false sense of security. Load determines whether a temperature difference is meaningful, and understanding load relationships is foundational to proper thermography.

Proper training explains when to scan, how to interpret ΔT (temperature difference), and how to separate load-related heating from true faults. Misjudge the load, and the entire inspection becomes unreliable.

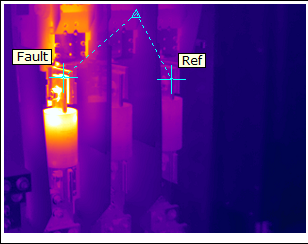

Mistake #3: Confusing Reflections With Real Heat

Reflectivity is one of the trickiest concepts in infrared thermography. Polished metal, stainless steel, aluminum, and many mechanical housings behave almost like mirrors. They reflect thermal radiation from the environment, including your own body heat.

Untrained users commonly mistake these reflections for overheating. They take a thermal image of a shiny bus bar or panel, spot a bright area, and assume a dangerous condition is present. In reality, nothing may be wrong with the equipment. The camera is simply capturing a reflection. This leads to unnecessary alarms, wasted time, needless repairs, and, in worst cases, shutdowns that were never required.

Training teaches how to work with reflective surfaces: adjust viewing angles, apply high-emissivity targets, validate readings, and confirm whether heat is genuine or reflected. Without this skill, a large portion of images can be misinterpreted.

Mistake #4: Ignoring Environmental Conditions

Thermography doesn’t happen in a controlled room. It happens in real-world environments full of variables that affect readings, including:

Wind or forced air cooling

Sunlight or solar loading

Ambient temperature fluctuations

Moisture evaporation

HVAC influences or other heat sources

These factors can dramatically alter what a camera sees.

For example:

Wind can cool an overheating joint enough to look “normal.”

A sun-soaked rooftop will radiate differently in the morning than late afternoon.

Moisture under insulation creates subtle temperature changes that beginners miss.

Training shows thermographers how to recognize and compensate for environmental effects, so they know when temperature patterns are meaningful and when they’re misleading.

Mistake #5: Using the Wrong Emissivity Settings

Emissivity is one of the most important concepts in infrared thermography, and one of the most consistently misunderstood. Emissivity determines how much infrared radiation a surface emits, thereby affecting the accuracy of temperature readings. Two objects at the same temperature can appear completely different if their emissivities differ.

Many beginners do not adjust emissivity at all, relying on camera defaults or guessing. But misconfigured emissivity settings can easily lead to temperature errors of tens or even hundreds of degrees. A component may appear dangerously hot when it is completely healthy, or vice versa.

Training teaches how to measure, adjust, and validate emissivity for different surfaces and conditions. Without this, temperature data becomes unreliable—and any decisions based on that data are equally unreliable.

Mistake #6: Inconsistent Technique From Scan to Scan

Infrared thermography is a discipline, not a set of random snapshots. Technique matters. Angle matters. Distance matters. Focus matters. Even posture matters. Small variations alter the quality and reliability of the data.

Untrained users often take each image differently from the last, making it impossible to compare one inspection to another.

Professionally trained thermographers follow documented, repeatable procedures, which are essential for trending, condition-based maintenance, and NFPA 70B compliance.

Mistake #7: Failing to Trend or Baseline Data Over Time

Equipment rarely fails instantly. It fails gradually, and those gradual changes are often visible thermally long before they become emergencies. Trending allows maintenance teams to identify deterioration, imbalance, mechanical fatigue, and other developing problems.

However, many users who rely on YouTube videos or casual learning treat thermography as a one-time event. They take a single scan, save a picture, and believe the job is done. Without trending, baselining, and comparison against historical readings, they lose the ability to detect slow progression.

Training teaches how to establish baselines, maintain documentation, and evaluate trends over time, which is exactly what NFPA 70B now requires for a compliant thermography program.

The Three Risks of Bad Training

When thermography is performed without proper training, organizations face three major risks:

Safety Risk: A missed anomaly can lead to equipment failure, fire, or electrical incidents. A false alarm can trigger unnecessary shutdowns or repairs.

Reliability Risk: Incorrect readings create misleading maintenance decisions, poor prioritization, and avoidable downtime.

Compliance Risk: NFPA 70B’s 2023 update shifted infrared inspections from “recommended” to “required”—and specified that they must be performed by qualified personnel.

Camera ownership does not imply qualification.

Training: The Safest, Smartest, Most Cost-Effective Solution

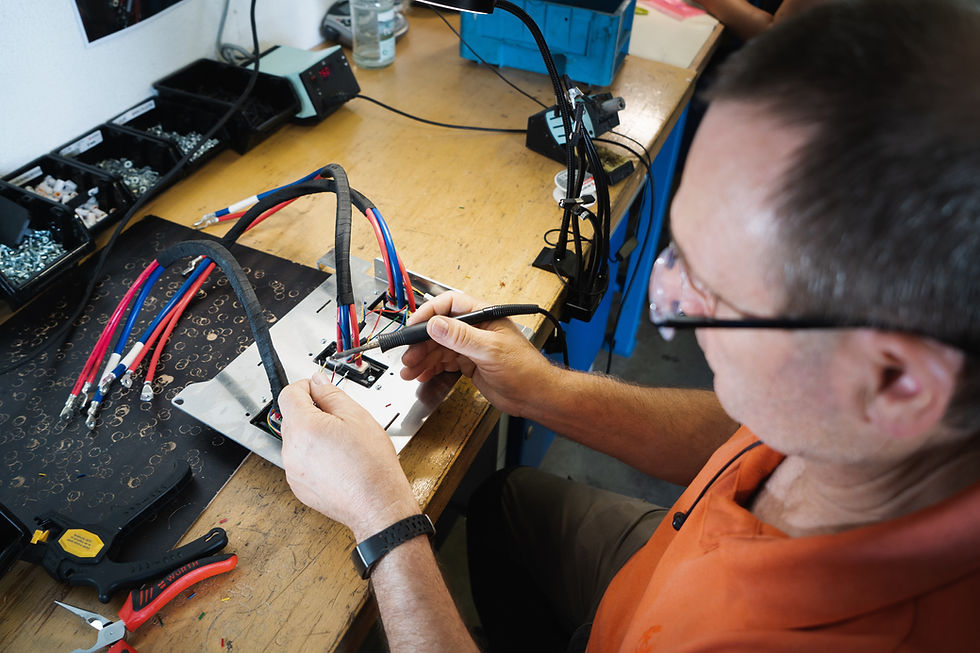

Professional infrared thermography training provides technicians with the knowledge, the technique, and the confidence to avoid every mistake described above. During Monroe’s Level I and Level II training programs, students learn the physics that drive thermal behavior, the practical methods for capturing accurate images, and the analytic skills needed to interpret data correctly.

Training covers:

Emissivity and reflectivity

Load conditions

Environmental considerations

Thermal patterns in electrical and mechanical systems

Building envelope analysis

Moisture detection

Trending and documentation

NFPA 70B compliance requirements

Thermography cannot be reduced to “point, shoot, and read the colors.” It requires professional instruction and hands-on practice to master.

The Camera Doesn’t Find Problems, Thermographers Do

Infrared thermography is one of the highest-value tools in any reliability or electrical safety program. But its effectiveness depends entirely on the knowledge and skill of the person behind the camera.

Untrained operators frequently misinterpret images, overlook failures, or confuse reflections with real heat—mistakes that compromise safety, reliability, and compliance.

Training is the difference between guessing and knowing. Between colors and meaning. Between a picture and an actionable diagnosis.

Get Started Today

Monroe Infrared, a Guidant Power partner, offers hands-on Level I and Level II thermography certification courses taught by seasoned thermographers with decades of field experience. Whether you need to train a single technician or certify an entire team, we deliver practical, compliant, confidence-building instruction that transforms thermography from a tool into a discipline.

View upcoming certification courses and reserve your seat → See the course list

Want guidance on where to start? →Contact our team today

70E®, Standard for Electrical Safety in the Workplace®, NFPA 70®, NEC®, and National Electrical Code® are registered trademarks of the National Fire Protection Association, Quincy, MA. All rights reserved. This informational material is not affiliated with nor has it been reviewed or approved by the NFPA.