Sorry, No X-Ray Vision: What Infrared Can and Cannot Do

- Christopher Casey

- Jan 12

- 6 min read

Updated: 3 days ago

Infrared thermography is one of the most valuable technologies available to modern electrical maintenance, reliability, and safety teams. It enables you to identify failing components, hidden anomalies, and high-risk conditions without shutting down equipment or opening energized gear. It’s fast. It’s safe. And when used correctly, it can detect developing failures long before they become emergencies.

Yet for all its value, infrared thermography is also one of the most misunderstood tools in industry. New users often approach it like a magic wand. Long-tenured technicians sometimes assume they can “figure it out” without training. And decision-makers often misinterpret what the technology actually reveals, and what it absolutely cannot.

As a result, many organizations underuse or misuse the tool, or fail to trust the data, because they’ve never been shown how infrared thermography truly works. Let’s take a look at both the capabilities and limits of thermography, why professional infrared thermography training is essential for accurate results, and how trained thermographers help organizations bridge the gap between data, safety, and operational reliability.

X-Ray Vision vs Surface Science

One of the most common misconceptions about infrared thermography is the belief that it can “see through” solid objects. Every infrared camera, regardless of brand, sensitivity, or resolution, measures thermal radiation leaving the surface of an object - emitted by the object. It does not penetrate walls, ceilings, roofs, metal switchgear, or glass.

When you point a camera at a wall, you see the temperature of the painted surface, not the temperature of the studs or moisture behind it.

When you point it at glass, you’ll usually see your own thermal reflection, not what’s inside the room.

When you point it at an energized electrical panel, you must still open the enclosure (following appropriate arc flash protocols) to view and read individual components.

This distinction is critical. Thermography cannot show you the future. It cannot reveal hidden chambers or structural voids. It cannot see through materials.

But what infrared can do is just as powerful.

What Infrared Can Reveal (When Used Correctly)

Thermal patterns on a surface often correlate with underlying physical processes. Even though the camera only measures surface temperature, the patterns can tell trained thermographers a great deal about what is happening beneath the surface.

Infrared Thermography Can Identify:

Loose or failing electrical connections: Resistance causes heat. An abnormal rise in temperature is one of the earliest signs of a developing electrical failure.

Overloaded circuits or phase: Imbalanced electrical loads heat unevenly. Thermography detects that imbalance before it cascades into a trip or failure.

Misaligned bearings, failing motors, or mechanical friction: Anything slowing motion generates heat — a key insight for mechanical reliability teams.

Moisture intrusion in roofs, walls, and insulation: Moisture changes thermal behavior due to differences in evaporation, heat capacity, and conductivity.

Air infiltration and energy loss: Air leaks appear as distinctive wispy patterns, especially when indoor/outdoor temperatures differ.

This allows maintenance teams to detect problems early, plan corrective work, reduce unplanned downtime, comply with NFPA and OSHA guidance, and reduce operational risk.

In short:

infrared thermography detects surface symptoms that can point to deeper root causes.

But interpreting those symptoms correctly still requires training.

Non-Contact, Non-Destructive, and Incredibly Safe

Another major advantage of infrared thermography is that it allows technicians to analyze energized systems without touching anything. This makes it ideal for high-risk electrical environments, systems where shutdowns are impractical, building envelopes, large mechanical systems, and a wide range of industrial equipment.

Unlike vibration probes, ultrasonic contact tools, or visual inspections that require opening or manipulating equipment, thermography collects data passively. The camera never contacts the equipment, and nothing is projected outward aside from a simple aiming laser. The risk of electric shock is dramatically reduced, and technicians avoid unnecessary arc-flash exposure.

Because infrared inspections do not disturb equipment, they prevent accidental damage and eliminate the wear-and-tear that can result from invasive diagnostics. For many organizations, this “non-contact, non-destructive” nature is why thermography has become the first-line inspection method for electrical safety and reliability programs.

The Problem With DIY Thermography: Why Training Matters

Infrared thermography is far more complex than it appears on the surface. Behind every thermal image is a mixture of radiative heat transfer, emissivity, surface reflectivity, transmissivity, environmental convection, load conditions, optical physics, camera calibration, temperature differentials, and trending analysis. Each of these factors influences what the camera sees, and what the operator thinks they see.

Despite this complexity, many new camera owners assume they can master thermography by watching a handful of YouTube videos, skimming manufacturer tutorials, or simply experimenting until the images “make sense.”

It’s a tempting shortcut, but a dangerous one.

If you don’t get trained properly, an IR camera is just an expensive stud finder.

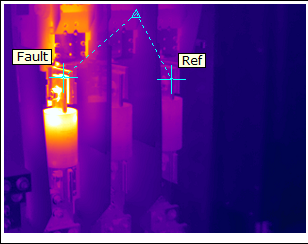

Self-paced learning fails for several reasons. First, most beginners don’t know what they don’t know. Without formal instruction, they have no way to recognize false positives, false negatives, reflected heat signatures, or other misleading artifacts. A polished metal panel, for example, might appear dangerously hot — when in reality, the camera is simply capturing the thermographer’s own heat reflected back.

Load conditions also play a critical role that untrained users rarely account for. A component showing only a slight temperature rise under minimal load may appear harmless, but that same component could exhibit a severe anomaly once the system ramps up to typical operating levels. Without understanding how load influences ΔT values, technicians can draw dangerously incorrect conclusions.

Environmental factors complicate things even further. Airflow from a nearby vent, wind across an outdoor panel, solar heating on a roof, humidity, and even the time of day can all distort thermal readings. Unless the operator knows how to compensate for these variables, the image can lie — and they won’t know it.

Finally, accurate thermography requires a structured, repeatable process. Scanning angles, distance to target, camera settings, and comparative analysis must all be controlled to ensure consistency. Guesswork simply isn’t good enough in environments where safety, compliance, and reliability depend on accurate data.

The bottom line is straightforward:

an untrained thermographer can easily miss critical failures or, even worse, declare unsafe equipment “normal.”

This is exactly why NFPA 70B no longer treats thermography as optional and now requires infrared inspections to be performed by qualified, trained personnel. Proper training is not a nice-to-have — it is the only way to ensure the data is trustworthy and the risks are correctly identified.

Why Trained Thermographers See What Others Miss

Professionally trained thermographers understand how to interpret what the infrared camera shows, and what it doesn’t. One Monroe customer reported that, literally on their first day after completing training and with their new IR camera and equipment, they found a transformer that was 450 degrees hotter than it should have been. If that component had failed, the entire plant would have shut down.

A YouTube-taught beginner likely would not have known to:

Check load conditions

Compare phases

Recognize the ΔT significance

Verify emissivity

Adjust and calculate for environmental effects

Understand transformer thermal limits

Training turns thermography from a visual gadget into a diagnostic instrument.

Why Infrared Thermography Training Should Be Mandatory

Infrared thermography training doesn’t need to turn someone into a physicist. But it does give professionals the foundational science, practical technique, and systematic methodology to capture and interpret accurate thermal data. High-quality training teaches technicians how to:

Adjust for emissivity and reflectivity

Capture consistent, reliable images

Analyze ΔT values properly

Trend thermal data over time

Report findings according to industry standards

Avoid common interpretation mistakes

Recognize dangerous conditions correctly

Validate equipment conditions with confidence

This is why NFPA 70B (2023) moved from “recommended” to “required” inspections performed by qualified, trained personnel.

Thermography Isn’t Magic; It’s Mastery

Infrared thermography is powerful, but only in the hands of trained professionals. It is a scientific tool, not a novelty camera. It is preventive medicine for buildings, equipment, and people.

And when applied with the right knowledge and technique, it delivers one of the highest returns on investment of any maintenance technology available today.

Don’t let your infrared camera become the world’s most expensive stud-finder. If you want accurate results, safer teams, and NFPA 70B compliance, training isn’t optional; it’s essential.

Get Started Today

Monroe Infrared, a Guidant Power partner, offers hands-on Level I and Level II thermography certification courses taught by seasoned thermographers with decades of field experience. Whether you need to train a single technician or certify an entire team, we deliver practical, compliant, confidence-building instruction that transforms thermography from a tool into a discipline.

View upcoming certification courses and reserve your seat

Want guidance on where to start? Contact our team today

70E®, Standard for Electrical Safety in the Workplace®, NFPA 70®, NEC®, and National Electrical Code® are registered trademarks of the National Fire Protection Association, Quincy, MA. All rights reserved. This informational material is not affiliated with nor has it been reviewed or approved by the NFPA.