Stop. Think. Report. Building a Culture That Learns from Close Calls

- Brian Hall & Jeff Kershner

- Sep 1, 2025

- 4 min read

Updated: Sep 3, 2025

No injuries. Two breakers tripped. A faint whiff of smoke.

That’s how close one recent incident came to being a serious electrical event.

The good news? It ended up being a priceless lesson.

For safety and facility leaders, moments like this are gold—if you treat them as the learning opportunities they are. Here’s how to use close calls to strengthen systems, sharpen skills, and build a reporting culture your team trusts.

What Your Facility Calls a Near Miss

Definitions vary, so pick one and make it explicit for your team.

At its simplest:

A near miss is any unplanned event that could have caused injury, equipment damage, or loss—but didn’t.

OSHA refers to a near miss as a potential hazard or incident in which no property was damaged and no personal injury was sustained, but where, given a slight shift in time or position, damage or injury easily could have occurred.

In electrical work, examples could include:

Finding an uncovered energized panel during maintenance

An unplanned breaker trip during panel work

PPE that wasn’t worn correctly inside the restricted or arc flash boundary

Tools or equipment damaged during electrical tasks

Why Near Misses Matter

Predictors: They’re leading indicators of serious events.

Free warnings: You get the lesson without the injury or outage.

Culture: Reporting builds trust, learning, and real risk reduction.

The American Society of Safety Professionals outlines Seven Principles for Building an Effective, Sustainable Near-Miss Management System, including defining what constitutes a near miss, encouraging reporting, and ensuring follow-up.

Human & Organizational Performance (HOP) reminds us:

Error is normal—even skilled workers make mistakes.

Systems drive behavior—look at conditions before blaming people.

Learning beats blaming—curiosity uncovers better fixes.

The Close Call: The Pinched Wire

What happened:

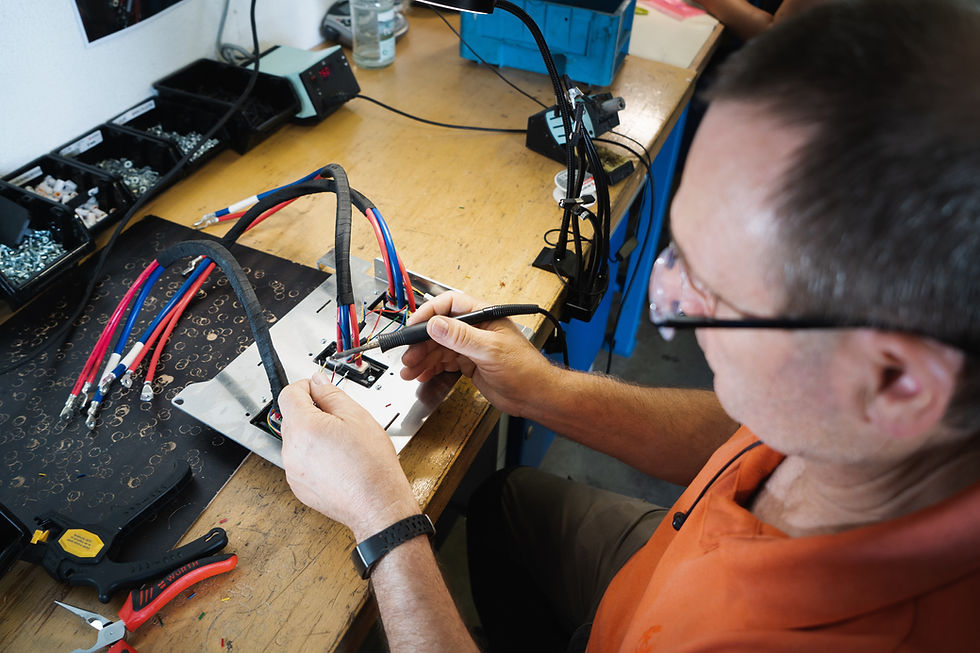

A new-to-site but experienced technician partially opened a panel cover to check conduit routing. After re-securing the cover, he stepped back to document the circuit. Seconds later, a breaker tripped, and light smoke was visible near one of the cover screws.

Inside, a conductor had been pinched against the cover bolt—likely already routed poorly before his work. The tech, wearing arc-rated daily wear and voltage-rated gloves, pushed the wire clear and reset the breaker before notifying the site contact. An upstream feeder breaker had also tripped.

What went right:

PPE was worn and effective

No one was within proximity at the moment of the fault

Protective devices operated as intended

What went wrong:

Attempted “fix and reset” before site notification

Poor conductor housekeeping in the panel

No pre-close check for potential pinch points

Key lesson: Secure conductors, never proceed in the face of uncertainty, and remember the OSHA* rule: you cannot re-energize until it’s determined the circuit can be safely energized.

For facility leaders, it’s crucial to ensure your procedures include detailed processes on what to do anytime a breaker trips or a fuse blows.

*OSHA 1910.334(b)(2). NFPA 70E® article 130.6(M) offers similar guidance.

Stop. Think. Report.

STOP

Use stop-work authority when conditions aren’t clearly safe. With SWA, any employee can halt work activities when conditions aren’t clearly safe, for example, when:

They are asked to perform energized work -- or work they are not trained for

There’s inadequate or no Lock-Out-Tag-Out (LOTO)

They are not provided with proper PPE.

Apply this concept any time you’re unsure how to proceed, either because of abnormal equipment behavior, or you or someone else doesn’t have reasonable certainty of safety.

If you are saying to yourself anything like: “I think…”, “Probably…”, or you see equipment in an abnormal condition or operating strangely, those are RED FLAGS.

This is supported by current laws: per OSHA, workers have the right to refuse work if there’s a reasonable belief of imminent danger.

THINK

Self-check: What’s different from normal? What could go wrong if I’m wrong?

Escalate PPE/controls or pause when outside “normal operation.”

REPORT

Notify your supervisor/site contact before resets or re-energization.

Capture the near miss within the same shift—voice note, quick form, or call.

5 Steps to Build (or Refresh) a Near-Miss Program

Define it clearly for your facility.

Make reporting easy—short form, QR code, or quick verbal process (OSHA sample form here).

Create a no-blame culture—focus on the work, not the worker.

Hold a rapid review huddle—10–15 minutes to identify fixes.

Close the loop—share what changed and recognize the reporter.

What to Capture in a Near Miss Report

Who/when/where (or anonymous)

Task & equipment involved

What was different or surprising

What prevented harm this time

Immediate actions & recommended fix

Use Near Misses as Teaching Tools

Toolbox talk playbook:

Share the story in 1 minute.

Ask, “What made this hard?” (2 minutes)

Agree on one small improvement this week (2 minutes).

Thank the reporter—publicly (30 seconds).

The Right Metrics

A strong near-miss program doesn’t just collect stories—it generates data you can use to elevate your safety culture. Tracking reports and outcomes over time gives you measurable insight into how well hazards are being identified, addressed, and prevented.

__of near misses reported per 100 employees

__% closed with corrective action in 30 days

__Time from incident to team share

__Top 3 hazard themes per quarter

Don’t just focus on the serious incidents. Build a robust near-miss reporting program to greatly reduce the chances of them happening at all. Remind all employees to be vigilant at all times, even when carrying out routine tasks. When something looks even slightly wrong, empower all workers to stop and stay safe.

Final Word

Near misses aren’t minor—they’re free lessons.

When you stop, think, and report, you’re building a safer workplace for the long term.

Whether you need a starter template, help training supervisors to lead near-miss reviews, or just want to get your reporting culture moving, Guidant Power can help.

Contact us today—or ask Jouleene, our virtual electrical expert (just click her icon to get started).

70E®, Standard for Electrical Safety in the Workplace®, NFPA 70®, NEC®, and National Electrical Code® are registered trademarks of the National Fire Protection Association, Quincy, MA. All rights reserved. This informational material is not affiliated with nor has it been reviewed or approved by the NFPA.