A Primer on Infrared Thermography Inspections: Who Needs One and Why

- Steve Oliver

- Dec 15, 2025

- 3 min read

How to spot electrical and mechanical problems long before they become dangerous or expensive

Infrared (IR) thermography inspections use specialized cameras to detect heat patterns and reveal risks that aren’t visible to the naked eye. It’s like getting an X-ray of your electrical and mechanical systems without shutting anything down.

Infrared inspections matter to several key roles: facility managers, QA/QC managers, operations leaders, and EHS professionals all have something at stake.

Facility Managers rely on them to keep equipment running and prevent unplanned downtime.

QA/QC Managers care because mechanical or electrical issues can lead to poor quality, rejected products, and, though far less often, products that may not be safe.

Operations Leaders want to avoid breakdowns that halt production.

EHS Professionals use these inspections to spot hazards before they escalate into OSHA-recordable incidents or fires.

Everyone benefits. IR inspections protect people, equipment, and performance, and implementing annual recommendations reduces surprises during your 5-year arc flash analysis. Also see Why Arc Flash Updates Still Cost Real Money Every Five Years — And Why They Matter for more details.

What Is Infrared Thermography?

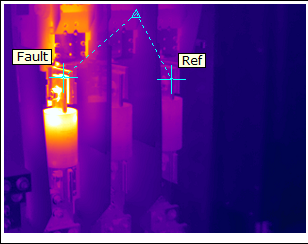

Infrared thermography is a non-contact method of “seeing” heat. IR cameras reveal loose connections, overloaded circuits, failing bearings, friction points, overheating molds, roof leaks, moisture issues, and more.

See figures 1 and 2 for an example.

Instead of reacting to failures after they’ve already happened, you get early warnings and time to fix issues ahead of time. It’s a first line of defense against electrical failures.

When Should IR Inspections Be Done?

According to NFPA 70B, IR inspections should be part of a routine electrical maintenance program. Most facilities complete them annually, with more frequent checks for critical operations. They’re also recommended after equipment upgrades, major changes, or whenever unexplained outages or heat-related problems appear.

Don’t wait for the next failure. Schedule before your next production cycle.

Where Do They Apply?

Infrared inspections are useful in a variety of settings:

• Electrical systems: switchgear, breakers, MCCs, transformers

• Mechanical systems: motors, pumps, bearings, conveyors, steam systems

• Building systems: roofing, insulation, moisture detection

No matter your industry, manufacturing, healthcare, data centers, utilities, IR gives you visibility where you need it most.

Why They Matter

Hope isn’t a safety strategy. Electrical incidents are rare but have some of the highest fatality rates in industry. IR inspections help you:

Detect problems before failures

Protect workers from arc flash, fire, and shock hazards

Reduce downtime

Support NFPA 70B programs and OSHA expectations

Safety is a smart investment, not a checkbox. Regular IR inspections and arc flash analyses are essential components of a strong safety program.

Experience Counts

At Guidant Power, our partnership with Monroe Infrared brings:

40+ years of experience

25,000+ inspections completed

Industry-leading thermography training

Our promise to you: clear, accurate, and actionable insights every time.

Final Word

Regular infrared inspections increase reliability, improve safety, and reduce costly surprises. Implementing recommendations consistently has been shown to pay off, year after year.

Ready to see your risks clearly? Get a quote for an infrared thermography inspection today.

70E®, Standard for Electrical Safety in the Workplace®, NFPA 70®, NEC®, and National Electrical Code® are registered trademarks of the National Fire Protection Association, Quincy, MA. All rights reserved. This informational material is not affiliated with nor has it been reviewed or approved by the NFPA.