Two Minute Drill for Electrical Safety

- Jeff Kershner

- Apr 1, 2025

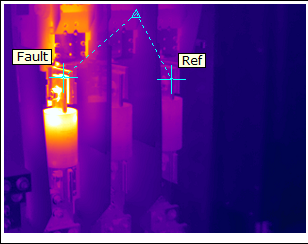

- 5 min read

Updated: Jun 12, 2025

A two-minute drill for electrical safety is a quick, focused safety check performed before starting any electrical work. It’s designed to identify and mitigate hazards in a short, actionable timeframe—typically about two minutes—ensuring that workers are aware of risks and prepared to address them.

This practice is especially critical in environments where electrical hazards like shocks, arc flashes, or electrocution are a concern, such as in construction, maintenance, manufacturing, or industrial settings. The goal is to create a moment of heightened awareness, confirm safety measures, and prevent incidents by catching potential issues before work begins.

Below is a step-by-step guide for conducting a two-minute drill specifically tailored for electrical safety. This drill can be used by electricians, maintenance workers, or any team working with or around electrical systems.

Two-Minute Drill for Electrical Safety - Example of beginning work After Performing LOTO

Step 1: Pause and Gather the Yourself (10 seconds)

Stop all activity and go to a distraction-free area near the work site.

Ensure those who might be indirectly affected are a part of your safety plan (e.g., workers nearby who could accidentally energize a circuit).

Step 2: Verify Lockout/Tagout (LOTO) Procedures (30 seconds)

Confirm that the electrical system you’re working on is de-energized:

Check that the correct circuit or equipment has been identified.

Verify that the power source is turned off at the breaker or disconnect switch.

Ensure locks and tags are in place, and confirm that each worker has applied their personal lock if required.

Confirm the Absence of Energy was Verified

Communicate with the team: “Is everyone clear that this circuit is locked out and tagged out? Has anyone not tested it?”

Step 3: Assess the Work Environment for Hazards (30 seconds)

Look for environmental or situational risks that could affect electrical safety:

Water or Moisture: Is the area dry? Are there any leaks, puddles, or damp surfaces that could conduct electricity?

Exposed Wiring: Are there any visible signs of frayed insulation, exposed conductors, or damaged equipment?

Grounding Issues: Is the equipment properly grounded? Are there any missing ground wires?

Proximity to Live Systems: Are there nearby live circuits or overhead power lines that could pose a risk?

Flammable Materials: Are there any combustible materials nearby that could ignite in case of a spark or arc flash?

Address any issues immediately—e.g., dry wet areas, isolate live circuits, or remove flammable materials.

Step 4: Check Personal Protective Equipment (PPE) and Tools (30 seconds)

Ensure everyone has the appropriate PPE for the task:

Ask the team: “Does everyone have the right PPE and tools? Is anything damaged or missing?

Step 5: Review the Task and Communication Plan (20 seconds)

Briefly go over the task to ensure everyone understands their role:

What specific work is being done (e.g., replacing a breaker, troubleshooting a motor)?

Who is responsible for what, and who has the authority to stop work if something feels unsafe?

Confirm communication protocols:

Establish a clear signal (e.g., verbal confirmation like “All clear!”) before proceeding.

Ask: “Does everyone know their role? Are we all on the same page?”

Step 6: Final Check and Commitment (10 seconds)

Do a quick mental scan for anything you might have missed:

Are there any new workers who might need extra guidance?

Has anything changed in the environment since the last check (e.g., new equipment, weather changes)?

Get a verbal commitment from the team: “Are we all ready to proceed safely? Any concerns?”

If anyone raises a concern, stop and address it before starting work.

Why This Drill Works for Electrical Safety

This two-minute drill is structured to address the most common electrical hazards and error precursors—like failure to de-energize, inadequate PPE, environmental risks, and poor communication—while keeping the process quick and actionable. It aligns with key electrical safety standards, such as:

OSHA 29 CFR 1910.333: Requires de-energizing live parts before work and using LOTO procedures.

NFPA 70E: Emphasizes hazard identification, PPE selection, and arc flash risk assessment.

Electrical Safety Foundation International (ESFI) Guidelines: Stresses the importance of testing for voltage and using proper tools.

Real-World Application In practice, this drill can prevent incidents in high-risk settings. For example, in a manufacturing plant, a maintenance team preparing to repair a 480V motor can use the drill to confirm the motor is de-energized, check for water on the floor (a common hazard in industrial settings), and ensure everyone is wearing arc-rated PPE. In construction, a crew working near overhead power lines can use the drill to verify that the lines are de-energized or that proper distancing is maintained, per OSHA’s 10-foot rule for unqualified workers (29 CFR 1926.1408).

Tips for Effective Implementation

Make It Routine: Perform the drill before every electrical task, no matter how small. Repetition builds a safety-first mindset.

Rotate Leadership: Let different team members lead the drill to keep everyone engaged and accountable.

Use Visual Aids: Some companies provide wallet cards with two-minute drill checklists. Create a similar card for electrical safety with key points like “Test for voltage,” “Check PPE,” and “Confirm LOTO.”

Encourage Participation: Ensure every team member speaks up, even if it’s just to say, “I’m good.” This fosters inclusivity and ensures no one is overlooked.

Adapt to the Task: Tailor the drill to the specific job. For example, if working on a high-voltage system, spend extra time on arc flash PPE and boundaries.

Potential Limitations

While the two-minute drill is effective for catching immediate hazards, it’s not a substitute for comprehensive electrical safety programs. It won’t address systemic issues like outdated wiring, lack of training, or insufficient safety budgets. It also relies on workers being diligent—if the team rushes through it or skips steps due to complacency, its effectiveness drops. Pair the drill with ongoing training, regular equipment maintenance, and a strong safety culture for best results.

A Broader Perspective

Some might argue that two minutes isn’t enough to catch every electrical hazard, especially in complex systems with multiple power sources. They’re not wrong—thorough risk assessments and job hazard analyses (JHAs) are still necessary for larger projects. However, the strength of the two-minute drill lies in its simplicity and immediacy. It’s a practical tool to refocus the team, catch obvious risks, and reinforce safety habits in the moment. Think of it as a quick huddle before the play, not the entire game plan.

In summary, a two-minute drill for electrical safety involves pausing to verify LOTO, assess the environment, check PPE and tools, review the task, and confirm communication. It’s a fast, effective way to mitigate electrical hazards and error precursors, ensuring workers stay safe while handling one of the most dangerous aspects of many jobs. By making this drill a habit, teams can significantly reduce the risk of electrical incidents.