Buying PPE: Be Careful of Wolves in Sheep’s Clothing

- Brian Hall

- Aug 4, 2025

- 2 min read

Updated: Aug 5, 2025

Why The Gloves You Bought Online Might Be Putting Your Team at Risk

During a recent electrical safety training session, a student mentioned a new type of glove he’d seen—a rubber glove that appeared to be fused to its leather protector. He said his coworkers at a nearby company had been using them and were impressed.

Curious, I asked for a photo. What he sent looked similar to gloves available from a major online retailer (see Fig. 1).

And that’s where I realized we had a problem.

Shopping Online? Buyer Beware

Online marketplaces make it easy to buy tools and PPE, but when it comes to life-critical safety gear, convenience can be dangerous. Many vendors source products globally, and not every country follows OSHA or U.S. consensus standards.

That means gloves that look legitimate may not be tested or approved for use in U.S. workplaces.

If those gloves fail during a task, the consequences could be fatal.

Why U.S. Safety Standards Matter

In the United States, electrical PPE standards are developed by the American Society for Testing and Materials (ASTM). For rubber insulating gloves, the key standard is ASTM D120, which outlines testing requirements for dielectric strength and physical integrity.

Gloves that meet this standard are clearly labeled and have passed rigorous performance tests. If your gloves don’t mention ASTM D120, they aren’t compliant. Do not use them.

OSHA Requirements for Electrical Gloves

OSHA standard 1910.137 mandates that rubber insulating gloves must meet ASTM D120. In addition, OSHA requires:

Periodic proof testing, typically every 6 months

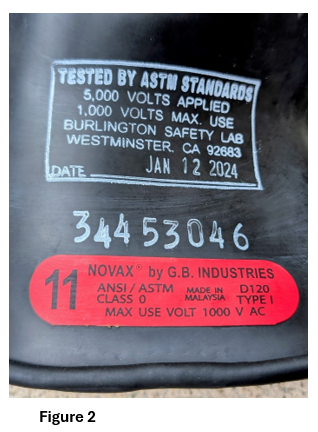

Permanent markings on each glove showing:

The glove class (voltage rating from Class 00 to Class 4)

The type (Type I for non-ozone resistant, Type II for ozone-resistant)

The manufacturer’s name or logo

The size

Markings must be nonconductive and placed on the cuff to avoid compromising glove integrity

See Fig. 2 for an example of compliant labeling.

If the label is missing, incomplete, or placed incorrectly, it’s a red flag.

Red Flags When Buying Online

Before you click “Add to Cart,” check the listing carefully:

❌ No mention of ASTM D120? Not compliant.

❌ No voltage class or type? Not compliant.

❌ Label placed outside the cuff or missing entirely? Not compliant.

✅ Verified ASTM labeling, correct placement, and clear specs? That’s what you want.

Just because something looks like safety gear doesn’t mean it meets U.S. standards. It’s your responsibility to verify. See fig. 3.

The Bottom Line: Looks Can Be Deceiving

Electrical PPE isn’t the place to cut corners or make assumptions. At Guidant Power, we’ve seen how easy it is to be fooled by gear that looks right but isn’t.

Before you put on your rubber insulating gloves:

Look for ASTM D120 compliance

Check for full OSHA-required labeling

Make sure your gloves have been tested at least every 6 months

If you’re unsure whether your current gloves meet standards—or want help evaluating what’s right for your team—talk to us. You can also ask Jouleene, our virtual electrical expert, by clicking the icon on the bottom right of the page.

When it comes to electrical safety, there’s no room for guesswork.

Further Reading: OSHA’s Guide to PPE